Metallurgical complex. Ferrous metallurgy. “Iron is not only the basis of the whole world, the most important metal of the nature around us, it is the basis of culture and industry, it is an instrument of war and peaceful labor. And it is difficult to find another element in the entire periodic table that would be so connected with the past, present and future destinies of mankind. A.E. Fersman RMO of teachers of geography of the Rzhev region (open lesson). Completed by: geography teacher Grechkina M.A.

1. Which of the American states is part of OPEC? a) USA; b) Mexico; c) Brazil; d) Panama; e) Venezuela; f) Chile 2. How many countries are members of OPEC? a) 5; b) 7; at 10 o'clock; d) 12; e) 15; 3.Where is the headquarters of OPEC? a) Istanbul b) Vienna; c) Warsaw; d) Brussels; e) London; 4. Most of the oil is produced: a) in the developed countries of Europe; b) c developing countries Asia; c) in the developing countries of Africa; d) in the developing countries of Latin America; 5. Which way are the largest oil tankers going? a) through the Suez Canal from the Persian Gulf to Europe; b) along the coast of Africa from the Persian Gulf to Europe; c) from Indonesia to Japan; d) from Venezuela to the USA; 6. Select the leading oil producing countries in Africa: a) Nigeria; b) Algeria; c) Libya; d) Egypt; e) South Africa; f) Angola; g) Zambia; h) Morocco 7. In Europe, the oil producing countries are: a) Denmark, Norway, Italy, Great Britain; b) France, Portugal, Switzerland; c) Finland, Sweden, Belgium, Greece; 8. Arrange the countries in descending order of proven oil reserves: a) Saudi Arabia; b) Russia; in the USA; d) Iran;

1. Which of the American states is part of OPEC? a) USA; b) Mexico; c) Brazil; d) Panama; e) Venezuela; f) Chile 2. How many countries are members of OPEC? a) 5; b) 7; at 10 o'clock; d) 12; e) 15; 3.Where is the headquarters of OPEC? a) Istanbul b) Vienna; c) Warsaw; d) Brussels; e) London; 4. Most of the oil is produced: a) in the developed countries of Europe; b) in the developing countries of Asia; c) in the developing countries of Africa; d) in the developing countries of Latin America; 5. Which way are the largest oil tankers going? a) through the Suez Canal from the Persian Gulf to Europe; b) along the coast of Africa from the Persian Gulf to Europe; c) from Indonesia to Japan; d) from Venezuela to the USA; 6. Select the leading oil producing countries in Africa: a) Nigeria; b) Algeria; c) Libya; d) Egypt; e) South Africa; f) Angola; g) Zambia; h) Morocco 7. In Europe, the oil producing countries are: a) Denmark, Norway, Italy, Great Britain; b) France, Portugal, Switzerland; c) Finland, Sweden, Belgium, Greece 8. Arrange the countries in descending order of proven oil reserves: a) Saudi Arabia; d) Iran; b) Russia; in the USA;

Ferrous metallurgy Technological features Placement factors Industry geography Industry development trends

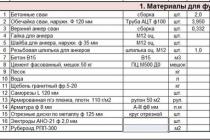

Technological process Includes: ore mining, beneficiation, smelting, rolling and production of ferroalloys. Raw materials Products Iron ore Coking coal Manganese, alloying metal ores Iron ore Coking coal Manganese, alloying metal ores Cast iron Steel Alloy steel Cast iron Steel Alloy steel

Cast iron is an alloy of iron and carbon containing permanent impurities (Si, Mn, S, P), and sometimes alloying elements (Cr, Ni, V). It is smelted from iron ore in blast furnaces. Steel is a malleable alloy of iron with carbon (up to 2%) and other elements. Obtained mainly from a mixture of cast iron with steel scrap in oxygen-converter and electric furnaces. Alloy steel - alloy. To give iron alloys certain physical or mechanical properties, alloying elements are introduced into the composition of ordinary steel grades - Cr, Ni, V, Mo, W, T.

The largest exporters of steel and rolled products The largest importers of steel and rolled products ChinaEU countries JapanUSA Russia South Korea UkraineChina Germany Benelux countries Benelux (Benelux) political, economic and customs union in Western Europe, which includes three monarchies: Belgium, the Netherlands and Luxembourg. Leading countries in the production of iron and steel products Cast iron, 2003 Steel, 2008 China India Japan Republic of Korea USA Brazil Russia India Romania Republic of Korea Kazakhstan Germany

Use of various methods of steelmaking, % of total production, 2008 CountrySteelmaking methods Oxygen-converter In electric furnaces In open-hearth furnaces Russia55,128,416.5 USA41,958.1-Japan75,224.8- Germany68,131.9 - Worldwide67,230,62,2

Placement factors 1.raw materials (proximity to ore deposits); 2. fuel (presence of a source of coking coal); 3. transport (especially important for enterprises operating on imported raw materials, far from sources of ore and coal); 4.ecological (ferrous metallurgy enterprises, especially outdated and using the blast furnace process, are among the most "dirty" industries); 5. consumer (the presence of a steel consumer - large machine-building centers).

Impact of scientific and technological revolution on ferrous metallurgy 1. Improving the quality of iron and steel and reducing their consumption per unit of final product 2. Reducing production losses 3. Reducing the raw material and fuel factor 4. Increasing consumer and environmental factors 5. Location of enterprises in coastal areas 6. Iron production in developing countries and steel production in developed countries Ore mining countries Steel smelting countries China Brazil Australia Russia India USA Ukraine Canada South Africa Venezuela China Japan USA Russia Germany Brazil India Ukraine France UK

Using the world ferrous metallurgy map in the atlas, select three or four examples of regions and centers that focus on: 1) a combination of coal and iron ore reserves; 2) reserves of coal; 3) iron ore reserves; 4) cargo flows of coal and ore. Using the world ferrous metallurgy map in the atlas, select three or four examples of regions and centers that focus on: 1) a combination of coal and iron ore reserves; 2) reserves of coal; 3) iron ore reserves; 4) cargo flows of coal and ore. In a notebook

Areas and centers focusing on: combination of coal and iron ore reserves coal reserves iron ore reserves cargo flows of coal and ore Anshan (China), Damodar (India), Transvaal (South Africa) Ruhr (Germany), Upper Silesia (Poland), Southern Wales (Great Britain). Magnitogorsk (Russia), Krivoy Rog (Ukraine), Lorraine (France), Annaba (Algeria), Volta-Redonda (Brazil) Cherepovets (Russia), Krakow (Poland), Kosice (Slavakia), Dunkirk and Foz (France), Toranto (Italy)

Industry Development Trends Use of the method of continuous casting of steel, out-of-furnace metallurgy (domainless), microalloying. Creation of mini-factories. There are many such factories in the USA, Japan, Italy, Spain, Mexico, Brazil. In the global smelting of ferrous metals, the share of developing countries is increasing and, at the same time, the share of developed countries is decreasing. In developed countries, the use of secondary raw materials (steel scrap) is of great importance. Creation of large steel monopolies (TNCs). The leaders are ArcelorMittal, Nippon Steel1, Baosteel Group.

Organizations related to the iron and steel industry The European Coal and Steel Community (ECSC) is an integration grouping of 12 EU member states. It controls almost all coal mining, over 90% of iron and steel smelting, about 50% of iron ore mining in Western Europe. Headquarters in Brussels.

Large metallurgical companies of the world "KRUPP" - a metallurgical and machine-building concern of Germany Founded: 1811 Sales volume: $ 8.4 billion Number of employees: 63 thousand people. "KRUPP" - metallurgical and engineering concern of Germany Founded: 1811 Sales volume: $ 8.4 billion Number of employees: 63 thousand people. "LTV" - a US company created as an electronic company, in 1974 and 1984 acquired metallurgical companies Founded: 1958 Sales: $ 7.5 billion Number of employees: 43.7 thousand people. "LTV" - a US company created as an electronic company, in 1974 and 1984 acquired metallurgical companies Founded: 1958 Sales: $ 7.5 billion Number of employees: 43.7 thousand people. MANNESMAN is a German pipe-rolling and engineering concern Founded: 1890 Sales: $11.6 billion Number of employees: 122,000 people MANNESMAN is a German pipe-rolling and engineering concern Founded: 1890 Sales: $11.6 billion Number of employees: 122,000 people NIPPON STEEL is a Japanese steel company Founded: 1970 Sales: $17.1 billion Number of employees: 67.8 thousand people NIPPON STEEL is a Japanese steel company Founded: 1970 Sales: $17.1 billion Number of employees: 67.8 thousand people

Conclusion Ferrous metallurgy is the basic industry. Raw materials and fuel factors play an important role in the location of metallurgical enterprises. The industry is characterized by a high concentration of production and combination. Solution of economic, environmental and social problems industry is associated with the modernization of production, increasing the volume and quality of products that are competitive in the domestic and foreign markets. These are additional jobs and a reduction in the tension of the environmental situation.

Task 1: Using the text of the textbook and maps of the atlas, fill in the table " Comparative characteristics Atlantic metallurgical base of the USA and Ruhr Germany" Practical work Comparable featuresPriatlantic base (USA) Ruhr base (Germany) 1.Geographic location 2.Raw materials and fuel resources 3.Main suppliers of raw materials 4.Main centers 5.Location factors

Homework Based on the text of the textbook, tables, drawings, maps of the atlas, give a detailed description of the world ferrous metallurgy. Plan: 1. The importance of the industry in the world economy, its sectoral composition, the impact of scientific and technological revolution on its development. 2. Dimensions of production with distribution by main geographic regions. 3.Main producing countries. 4.Countries-exporters and importers. 5.Environmental and environmental problems arising from the development of the industry. 6. Prospects for the development and location of the industry.

Oil is the most traded resource in the world. Oil is an instrument of political and economic influence. Oil is the driver of technological development. Moreover, huge funds are being invested not only in the creation of new methods for the extraction and processing of black gold. For the transportation of raw materials, the most complex engineering structures such as supertankers and trunk pipelines

Icebreakers help tankers transport oil from the Novoportovskoye field

Exchange instrument

The path of oil to consumers begins long before it gets from the reservoir to the well - at the moment of concluding a contract for the supply of raw materials. Today, two mechanisms are used to sell oil: futures and spot. Futures contracts (as a rule, exchange contracts) are concluded for the supply of a batch of raw materials in the future. At the same time, the volume of one contract and the quality of raw materials are set in advance and are known to all market players. And at the time of the conclusion of the transaction, the parties agree only on the price and delivery time.

The cost of non-marker grades of oil is calculated with a discount or a premium to the standards. For example, oil from Gazprom Neft's Novoportovskoye field, due to its high quality, is traded at a premium to the benchmark North Sea Brent blend.

The practice of working with futures was first used in the early 80s at the New York Mercantile Exchange (NYMEX) and very quickly became the main one, as it made it possible to streamline pricing mechanisms. For futures contracts for oil, the volume of one contract, as a rule, is 1 thousand barrels, and the quality of raw materials is determined by the grade of oil. There are several benchmark (or marker) grades of oil identified around the world that are typical of major refining centers (see inset on page 7). The cost of non-marker grades of oil is calculated with a discount or a premium to the standards. For example, the Russian export brand Urals trades at a discount to Brent. The conclusion of a futures contract for the purchase or sale of oil almost never means the delivery of a specific physical volume of raw materials. Today, it is rather a tool of the exchange game, based on the multidirectional reaction of quotations to world economic and political events. For example, on the London Stock Exchange (ICE) about 70-100 thousand futures contracts are made per day, on the NYMEX - about 150 thousand, however, of all this gigantic volume, often exceeding the actual daily production volume, physical deliveries do not exceed 1-3% .

Real transactions are made in the spot market. Its main feature is that new property rights arise at the time of the transaction. As for the physical deliveries of raw materials, two days are allotted for them, although most often we are talking only about entering the name of the new owner in the database.

Approximately 50% of the world's oil is sold under long-term contracts that oil companies enter into with refiners (sometimes through intermediary traders). Such transactions are the main mechanism for trading in Russian oil. In this case, the price of oil is determined by a certain formula, which is synchronized with market quotes from time to time.

The Trans-Alaska Highway is designed to withstand an earthquake of up to 8.5 magnitude. Its route follows a zigzag broken line to compensate for stresses caused by soil displacement during very strong longitudinal seismic vibrations.

About a third of the world's oil is sold in single batches. The main spot trading platforms are Rotterdam, Singapore, New York, that is, economic and port centers where powerful oil terminals are located, as well as territories where oil trunk pipelines pass.

sea routes

It so happened that the main world centers of oil production and consumption are separated by thousands of kilometers. Most of the black gold is produced today by Russia (10.11 million barrels per day in 2015) and Saudi Arabia (9.74 million barrels per day). At the same time, the United States (19 million barrels per day) and China (10.12 million barrels per day) have the highest demand for oil. Huge volumes are also consumed by India and Japan, which, unlike the United States and China, have practically no oil reserves of their own.

How to ship raw materials from the Middle East and Africa to the USA, Europe or Japan? Of course, by sea. Tanker transportation today accounts for about 60% of the total oil cargo traffic.

Supertanker Knock Nevis

Supertanker Knock Nevis

According to archaeological data, the first "tankers" appeared more than 8 thousand years ago. Oil produced on the banks of the Euphrates was delivered downriver to the city of Ur in special bulk vessels with a carrying capacity of up to 5 tons. But this practice was subsequently forgotten - until the last third of the 19th century, oil was transported in barrels and amphoras on board ordinary ships. This continued until mankind realized how valuable this raw material was, and began to extract and use it on an industrial scale.

From the Arctic to Europe

A unique scheme for transporting produced oil to consumers has been created at Gazprom Neft's Novoportovskoye field. Raw materials from the field to the coast of the Gulf of Ob are delivered via a pressure oil pipeline with a length of more than 100 km. The infrastructure created at the field and onshore allows transshipment of up to 8.5 million tons of oil per year. Year-round shipments of raw materials are provided by the Gates of the Arctic oil loading terminal - the only such facility in the world located in fresh waters beyond the Arctic Circle. Further, oil is delivered by medium-tonnage tankers, accompanied by nuclear-powered icebreakers, along the Ob Bay and the Northern Sea Route to the Kola Bay. There, oil is loaded onto large-capacity tankers via the Umba floating storage tank and shipped to consumers in Northern Europe. To organize this logistics scheme, Gazprom Neft is currently building its own tanker fleet.

The first oil tanker was the wooden sailing schooner "Alexander", converted for this purpose in 1873 by Astrakhan merchants, brothers Nikolai and Dmitry Artemyev. The effectiveness of the new method can be assessed by the dynamics of oil transportation from Baku to Astrakhan. In 1874, when oil was still delivered in barrels, the volume of transportation of raw materials amounted to 10 million poods, in 1884 - already 50 million poods, and in 1894 - 208 million poods.

657 thousand tons - the carrying capacity of the largest tanker in the world, Knock Nevis, built in Japan

The world's first metal oil tanker, the Zoroaster steamer with a carrying capacity of 250 tons, was built at the Lindholmen shipyard in Gothenburg in 1877–1878 by order of the Russian Nobel Brothers Partnership. It sailed the Caspian Sea and became a real prototype of modern tankers, even in terms of security. For example, for firefighting purposes, the cargo holds of the Zoroaster were separated from the engine room by a double partition, into which water was poured. And at the Russian steam tanker "Savior" with a carrying capacity of 670 tons, built in 1882, the engine room for the first time in world practice was moved to the stern - the way it is done on modern ships.

The carrying capacity of oil tankers increased very slowly. In the mid-1950s, it was about 15 thousand tons, in the 1960s - 30 thousand tons. The era of supertankers (ULCC, Ultra Large Crude Carrier) began in the next decade. From 1976 to 1980, 126 giant oil tankers were built, capable of carrying two hundred thousand tons of black gold. The largest tanker in the world was built in Japan - it's Knock Nevis with a displacement of 657 thousand tons.

However, the time of giant tankers did not last long. Their appearance was largely a response to the unstable political situation in the Middle East, which led to the closure of the Suez Canal. The huge flow of oil to Europe and America needed to be redirected around the African continent through the Cape of Good Hope.

As soon as the six-day war between Israel and Egypt ended, the need for so many giant ships, unable due to the large draft to move through the shallow Suez Canal, disappeared. Moreover, the oil crises of the 1980s and rising prices for raw materials reduced the consumption of hydrocarbons in developed countries, in parallel with this, large fields were put into operation in the North Sea and North Africa, and as a result, a third of the world's tanker fleet turned out to be superfluous. Most of the supertankers were converted into stationary floating oil and water storage facilities.

The main export route for Middle Eastern oil continues to pass through the Cape of Good Hope. Another powerful oil flow is sent from the ports of the Mediterranean Sea and North Africa to the countries of Western Europe through Gibraltar. Such a large consumer of hydrocarbons as Japan also receives raw materials by sea from the countries of the Middle East, Malaysia and Indonesia.

Petroleum products from the Moscow Oil Refinery enter the 380 km main oil product pipeline, which encircles the capital in a ring

Petroleum products from the Moscow Oil Refinery enter the 380 km main oil product pipeline, which encircles the capital in a ring

However, in order for oil to be loaded onto tankers, it still needs to be delivered from the fields to the ports. The cheapest way to do this is to use oil pipelines.

Oil in a pipe

People have been using various pipelines or their similarities for several thousand years. However, for the first time, the Russian scientist Dmitry Mendeleev suggested using a pipe for transporting oil. In 1863, visiting the oil refinery of Vasily Kokorev near Baku, he proposed to pump raw materials through pipes from the fields to the plant and kerosene from the plant to the shipping pier in the Caspian. But, as has happened many times in history, in Russia the idea was not put into practice, and the Americans seized the palm.

The world's first oil pipeline with a diameter of 50 mm and a length of 6 km was built in 1865 in Pennsylvania by Standard Oil. He allowed John D. Rockefeller to bring down the price of oil by rail.

In Russia, the first oil pipeline appeared only in 1879. With his help, engineer Vasily Shukhov connected the Balakhani field on the Absheron Peninsula with oil refineries in Baku, the distance between which was 12 km. According to the project of Vasily Shukhov, in 1907 the first domestic main pipeline was built, 813 km long, connecting Baku and Batumi. In principle, the highways of the beginning of the century differed little from their modern counterparts.

The first "tankers" appeared more than 8 thousand years ago. Oil produced on the banks of the Euphrates was delivered downriver to the city of Ur in special bulk vessels with a carrying capacity of up to 5 tons. Subsequently, until the last third of the 19th century, oil was transported in barrels aboard conventional ships.

Main oil pipelines are laid to deliver oil from production sites to transshipment and processing points, and they differ from internal oil pipelines in the fields in their significant performance characteristics. The length of main oil pipelines can be thousands of kilometers, and oil moves through the pipes at a speed of up to 3 m/sec. due to the difference in pressure created by pumping stations, which are located every 70–150 km. The diameter of the main pipes ranges from 219 to 1400 mm, and the excess pressure is from 1.2 to 10 MPa.

A modern oil pipeline is a high-tech facility. Oil pumping and control of its systems is carried out remotely, using computers. A lot of sensors collect information about the state of the pipe, shut-off valves allow you to quickly shut off the emergency section of the pipeline. Internal cleaning of the pipe is also carried out using modern intelligent robotic systems. The pipes themselves, as a rule, are made from high-ductility steels that can withstand temperature, mechanical and chemical influences.

arctic experience

During the development of the Vostochno-Messoyakhskoye field in the north of the YNAO, Gazprom Neft built an oil pipeline in the most difficult conditions of the Arctic. To deliver oil from the field to the Transneft system, the company built a pressure pipeline 98 km long and with a capacity of 8.5 million tons of oil per year. When designing it, not only the harsh climatic conditions of the region were taken into account (in winter, the air temperature in Gydan often exceeds -50 ° C), but also the difficult terrain, and in addition, the impact of the project on the life of the indigenous population and on the environment. The route of the oil pipeline does not cross sacred places for indigenous people and deer grazing lands. Special crossings were built on the migration path of reindeer herds, and the large rivers Muduyahu and Indikyahu, along whose channels reindeer herds also move in winter, and small boats move in summer, the pipe crosses underground. These are the northernmost underwater crossings in Russia, made using the directional drilling method.

Pipeline geography

The world's longest system of main pipelines today belongs to the Russian Transneft - over 70 thousand km, more than 90% of all Russian oil produced passes through the pipe. All large oil refineries of the CIS countries are connected to the system, which began to take shape in the USSR in the postwar years. The Soviet Union also has the merit of building the first trans-European oil pipeline: the Druzhba oil pipeline brought Soviet oil to European market, making the country a key supplier for the socialist camp.

After the collapse of the Soviet Union and the socialist camp as a whole, Druzhba lost its strategic and, most importantly, political significance. Moreover, the pumping of oil through it began to bear quite serious transit risks, which Transneft reduced by laying the Baltic pipeline system(BTS), providing direct access to the Russian port of Primorsk. The first part of the BPS was put into operation in 2006, and in 2012 BPS-2 was launched, linking the Druzhba oil pipeline (in the Unechi region on the Russian-Belarusian border) with the Baltic port of Ust-Luga.

Another important factor development of the Russian oil pipeline system - the search for new markets. The rapidly developing economies of the Asia-Pacific region have made this market a tasty morsel for all energy suppliers. Russia's interest in new consumers resulted in the construction of the Eastern Siberia - Pacific Ocean (ESPO) pipeline system. The first 1,100-kilometer section of the pipeline was launched in 2009, and today the pipeline connects Taishet (Irkutsk region) with the city of Skovorodino on the Russian-Chinese border and then goes to the port of Kozmino in Primorsky Krai.

The United States also has a powerful and extensive pipeline system, which today has received a new impetus to development. Rising oil production in the United States, reduced imports caused a shortage transport capacities, and, according to the consulting company Wood Mackenzie, the volume of investments in the construction of new oil pipelines in the coming years will exceed $40 billion.

The main directions of transportation of Russian oil through pipelines

However, one of the most famous in America (and in the world) oil pipelines has already been built - the Trans-Alaska Mainline. The pipe with a diameter of 1220 mm is intended for pumping oil produced at the Prudhoe Bay field in northern Alaska to the port of Valdez in the south of the state. Its length of 1,288 km is not a record, but it's all about the conditions in which the construction of the oil pipeline was carried out: low temperature and difficult, isolated terrain. This is one of the most protected pipelines in the world - it is designed to withstand an earthquake of up to 8.5 magnitude. To do this, the pipe is laid above the ground on special supports with compensators that allow it to slide along special metal rails in a horizontal direction by almost 6 m and vertically by 1.5 meters due to a special gravel pad. In addition, the route of the oil pipeline was laid along a zigzag broken line to compensate for stresses caused by soil displacement during very strong longitudinal seismic vibrations and during thermal expansion of the metal.

At the end of 2016, the main oil pipeline was built in Russia in the most difficult northern conditions. The Zapolyarye-Taishet pipeline connects new fields in the north of the Yamalo-Nenets Autonomous Okrug with the Transneft system, including the Messoyakha group of Gazprom Neft.

Flexibility and versatility

Of course, rail and road transport is used to transport oil and oil products. By rail, oil is delivered to regions remote from fields where there are no branches of main pipelines, for example, from Western Siberia on the Far East, and from the Urals - to the south: to Novorossiysk, to the North Caucasus.

Oil is transported by tank trucks from remote oil fields to collection points, and sometimes to the “mainland”. As a rule, this happens at an early stage of field development, before the commissioning of oilfield pipelines. For example, oil was exported from the Novoportovskoye and Vostochno-Messoyakhskoye fields of Gazprom Neft during the pilot operation period.

However, the efficiency of trains and tankers is much lower than that of tankers and pipes. For example, the labor required to transport oil across railway, 10 times higher than for oil pipeline transportation, and road transport is even more expensive. But for the transportation of petroleum products, rail and road transport is used very actively. Railway shipments are optimal for transporting petroleum products from refineries to tank farms.

However, pipeline transport is successfully used here as well.

A unique transport system has been built in the Moscow region. This is the main oil product pipeline (MNPP) in three lines with a length of 380 km (1151 km in single-line terms), enclosing the capital in a ring. The MNPP corridor runs approximately 50 km from the Moscow Ring Road. The presence of three threads allows you to separately transport gasoline, diesel fuel and aviation kerosene. An example in the organization of the Moscow oil product transport system was the Northern capital, where the pipeline from the nearest oil refinery in Kirishi was commissioned in 1971 and solved the problem of supplying the city, region and Pulkovo airport with oil products.

Oil grades

For Europe and Asia, the reference grade of oil is Brent. It is a blend of crude oil from 15 North Sea fields. The American standard is WTI (West Texas Intermediate). The Middle East has its own Middle East marker grade (a mixture of Dubai and Oman oils). The Organization of the Petroleum Exporting Countries (OPEC) has created a “basket” of seven grades as a benchmark: light oil from Saudi Arabia (Saudi Arabian Light crude), Dubai (Dubai crude) from the UAE, Nigerian light (Nigerian Bonny Light crude), Saharan Blend from Algeria, Indonesian Minas, Venezuelan Tia Juana and Mexican Isthmus. The main Russian export brand Urals is a mixture in the Transneft pipeline system of heavy, sour oil from the Urals and the Volga region. After the start of production on the Prirazlomnaya platform, a new grade of oil appeared in Russia - Arctic Oil (ARCO).

Vladimir Khomutko

Reading time: 4 minutes

A A

Map of the world oil fields is quite large, but everywhere the process of oil and gas production takes place with the help of wells that are drilled in the rock mass using drilling rigs. They are familiar to many from films in which they showed lattice cone-shaped " oil rigs". These are drilling rigs, which, after organizing the well, are dismantled and transported to another place.

The places where such mining takes place are called fields or deposits. Transportation of oil and gas from fields to processing enterprises engaged in the production of marketable petroleum products is carried out through pipelines.

Drilling a well can take several days, or it can take several months.

Oil and gas wells are not just holes in rocks. Their trunk is cased from the inside with special steel pipes called tubing (tubing pipes). Through them, hydrocarbons are extracted to the surface.

Outside, the main pipe string, called the production string, is cased with others - casing pipes that strengthen the wellbore and isolate the various earth formations from each other. The length of the shaft of such a working can reach several kilometers.

To prevent the various rock layers from communicating with each other, the free space behind the casing pipes is usually cemented. This makes it possible to prevent the interlayer circulation of water, gases and oil itself.

The cement ring arranged behind the casing strings is destroyed over time due to physical and chemical influences, resulting in behind-the-casing circulation. This phenomenon has a negative impact on the extraction of black gold, because in this case, in addition to the necessary oil, gases or waters from neighboring rock layers enter the wellbore from the reservoir, called the reservoir, and their amount often exceeds the volume of the oil itself.

In order for the produced resource to enter the wellbore at all, it is necessary to punch holes in the casing and the cement layer behind it, since both the casing and cement isolate the reservoir from the well. Such holes are made using special shaped charges that penetrate not only cement and casing pipes, but also form holes in the oil reservoir itself. This process is called perforation.

Oil production methods are different, and depend on the pressure in the reservoir. Oil production is carried out using various technologies. Oil can flow on its own, in other words, it can rise along the wellbore from the reservoir to the surface without the help of pumping equipment, due to its low density.

If oil is extracted without the use of additional pumping equipment, then this method of oil production is called free flow.

The essence of the flowing process is that the hydrostatic (water) pressure in the reservoir at a depth is quite high (for example, at two kilometers it will be about 200 atmospheres). This indicator is called reservoir pressure.

Since the density of oil and gas is less than that of water, then at the same depth the pressure in the wellbore, which is called bottomhole pressure, will be (with a raw material density of about 800 kilograms per cubic meter) approximately 160 atmospheres. As a result of the resulting depression (pressure drop) between the productive formation and the wellbore, oil rises up.

In addition, oils, as a rule, contain light hydrocarbon compounds, which, in the event of a decrease in pressure, become gaseous (gases dissolved in the oil mixture). The release of such gases further reduces the density of the extracted raw materials, as a result of which the depression described above intensifies. This process can be compared to opening a warm bottle of champagne, from which a powerful carbonated fountain flies out.

The amount of raw material received from the well per day is called by experts the well flow rate (not to be confused with the accounting term “debit”). Gradually, especially during intensive production, reservoir pressure in the reservoir decreases, obeying the law of conservation of energy. As a result, the well flow rate decreases, since the pressure drop between the reservoir and the mine shaft becomes insignificant.

To increase the reservoir pressure, water is pumped into the reservoir from the surface using injection wells.

In some types of reservoirs, in addition to oil, there is immediately a large volume of formation water, due to the expansion of which the drop in in-situ pressure is partially compensated, and the need for additional water injection may not arise.

In any case, water gradually seeps into the developed oil-saturated layers of the reservoir, and through them into the wells themselves. This process is called watering, which also causes a decrease in production. This is due not only to a reduction in the proportion of oil itself in the produced mixture, but also to an increase in the density of the watered oil mixture. Bottomhole pressure in mine workings with a high degree of water cut increases, which leads to a decrease in drawdown. Eventually the well stops flowing.

In other words, the flow rate of any well is gradually decreasing. Usually, maximum value this parameter is reached at the very beginning of reservoir development, and then, as oil reserves are depleted, the flow rate decreases, and the more intensive oil production is, the faster this decrease is. In other words, the higher the initial flow rate, the faster it will fall.

In order to return the well to its previous productivity, various works are carried out on the wells in order to intensify production. Carrying out such work, as a rule, leads to an instant increase in production, but after that they begin to fall at a faster pace. At Russian oil wells, the rate of debit decline ranges from 10 to 30 percent per year.

In order to increase the flow rate of production wells with either a high degree of water cut, or with formation pressure that has fallen below the prescribed level, or with a low level of concentration of dissolved gases, various technologies of the so-called artificial lift are used. And the main such methods are methods using pumps. various types, the production of which is currently highly developed.

The most widespread are the well-known "rocking chairs", which are called sucker rod pumps (abbreviated as SRP). Also quite common are centrifugal pumps with an electric drive (abbreviated as ESP), which are not visible on the surface. The main oil production in the Russian Federation is currently produced using ESP.

The principle of operation of all pumping production methods is based on lowering the bottomhole pressure, resulting in an increase in drawdown and, as a result, flow rate.

The mechanized technological process is not the only way out in the event of an artificial increase in well productivity.

For example, the so-called hydraulic fracturing or gas lift technique is often used, but these are topics for separate articles.

Oil fields can be developed both at high bottomhole pressure and at low bottomhole pressure. If the bottomhole pressure is high, then the drawdown decreases, the flow rate decreases, and the reserves, although they are extracted, but at a slow pace. If, on the contrary, the bottomhole pressure is low, then the drawdown increases and the flow rates increase significantly, which leads to high pace development of stocks of raw materials.

Some features of the oil industry

Often, with a high intensity of field development, the term “predatory exploitation” or “predatory mining” is used, which have a pronounced negative connotation. At the same time, it was assumed that during such operation of wells oil companies, representing the oil industry, as it were, “skimmed the very cream” from the fields being developed, or extracted easily accessible raw materials, and the rest of the reserves were simply abandoned, in which case it became impossible to raise the remaining oil to the surface.

In most cases, this statement is incorrect. In most of the oil fields, the remaining hydrocarbon reserves do not depend on the intensity of their production. As evidence, we can cite the fact that a sharp increase in the amount of Russian oil produced occurred in the late twentieth - early twenty-first century, but seventeen years have passed since then, and the volume of domestic oil produced does not even think to decrease (the level of 2015, to for example, compare with the level of 2000).

And such a period for oil fields is quite long. In this regard, if the rate of development of oil reserves would lead to the loss of raw materials remaining in the reservoirs that have not yet been extracted, then the volumes have long begun to decrease, but this is not happening.

High intensity operation increases the risks associated with the possibility of emergencies, for example, due to the destruction of the cement layer around the wellbore, which leads to unwanted circulation in the annulus and premature breakthroughs of formation waters. However, in the general case, such a production regime is almost always economically justified, and at almost any level of oil quotations. For an illustrative example, you can compare this with a traffic situation.

If, for example, you limit the speed of cars outside the city to twenty kilometers per hour, and then use draconian measures to force this limit to be strictly observed, then with a high degree of probability the number of accidents will be minimal (if any). But why then will these roads be needed from an economic point of view?

As we said earlier, the increase in the intensity of Russian oil production occurred at the turn of the twentieth and twenty-first centuries.

In most cases, production was carried out by lowering the pressure in the bottomhole (respectively, the drawdown increased) in the operated wells. To do this, pumps were lowered into the flowing workings, and the wells, on which pumping equipment had already been installed, were replaced with more productive ones.

And there was and is nothing unequivocally bad in this, neither from a technical nor from an economic point of view. To negative consequences Such a production method can only be attributed to a strategic factor, since an increase in drawdown, although it leads to an increase in the rate of oil production, on the other hand, the decline in production rates in already drilled productive areas is accelerating.

Since oil well rates are constantly falling, in order to maintain oil production at a certain level, it becomes necessary to drill new wells, and the faster the rates fall, the more such mine workings must be drilled every year. In other words, intensive production leads to the fact that it becomes more and more difficult to maintain a certain constant volume of oil production every year.

On the other hand, if the operation of wells does not differ in intensity (due to high pressure in the face), then for such fields there is an opportunity to increase production volumes at the right time (using various methods by reducing the value of the pressure in the face). This is exactly how the regulation of the volume of extracted raw materials in Saudi Arabia and Kuwait takes place. In this regard, from a strategic point of view, a low intensity of oil production is safer.

Grade 10. fuel and energy complex Option 1

1. Which of the American countries is part of OPEC?

A) USA b) Mexico c) Brazil d) Panama e) Venezuela f) Chile

2.Where is the headquarters of OPEC located? a) Istanbul b) Vienna c) Warsaw d) Brussels e) London

3. Which way are the largest oil tankers going?

a) Through the Suez Canal from the Persian Gulf to Europe; c) from Indonesia to Europe;

B) along the coast of Africa from the Persian Gulf to Europe; d) from Venezuela to the USA.

4. In Europe, the countries producing oil are:

a) Denmark, Italy, Norway, Great Britain;

B) France, Portugal, Switzerland;

C) Finland, Sweden, Belgium, Greece.

5. Match:

1. Countries that mine coal only for their own use.

2. Countries exporting part of the coal. a) Japan, USA, Italy, UK, France.

3. Importing countries. b) India, Kazakhstan, Ukraine, Germany, Great Britain.

C) China, Australia, Russia, Poland, Canada, South Africa.

6. Match:

1. HPP a) Canada, Norway, New Zealand, Brazil, Tanzania, Nepal;

2. TPP b) France, Japan, South Korea, Sweden, Belgium;

3. NPP c) South Africa, Germany, Australia, USA, China.

7. Among countries of Eastern Europe According to the reserves of hydropower resources, the following are distinguished:

1) Latvia and Lithuania; 2) Poland and the Czech Republic; 3) Bulgaria and Macedonia; 4) Romania and Slovakia.

8. The main coal-producing countries are: A) developed B) developing

9. The highest share of energy produced at nuclear power plants is typical for:

A) for Poland B) for France C) for Norway

10. Why is oil transported from the countries of the Middle East along Africa and through the Suez Canal? Isn't it more profitable to carry all the oil through the Suez Canal? After all, this way of transportation is shorter.

11. How to explain that Japan, occupying the second place in the leading eight countries in the production of industrial products, by consumption of primary energy resources per capita ranked fourth?

Grade 10. fuel and energy complex Option 2

1. How many countries are included in OPEC? a) 5 b) 7 c) 10 d) 12 e) 15

2. Most of the oil is produced:

a) in the developed countries of Europe; c) in the developing countries of Africa;

B) in the developing countries of Asia; d) in the developing countries of Latin America.

3. Select the leading oil producing countries in Africa:

a) Nigeria b) Algeria c) Egypt d) Libya e) South Africa f) Gabon g) Morocco

4. Arrange the countries in descending order of proven oil reserves.

1. Saudi Arabia 2. Iran 3. Russia 4. USA

5. The share of what type of fuel reached 80% in the 20th century? a) gas b) coal c) uranium d) oil

6. Match:

1. The country ranks 10th in terms of electricity production, the share of hydroelectric power plants is 93%. A. France

2. The country ranks 7th in terms of electricity production, the share of nuclear power plants is 77%. B. Russia

3. The country ranks 4th in terms of electricity production, the share of thermal power plants is 72%. B. Brazil

7. Establish a correspondence in the power generation structure:

1. TPP A. 17%

2. HPP B. 20%

3. NPP B. 62%

4. Alternative power plants D. 1%

8. The largest oil producers in the world are the countries:

A) Western Asia B) Africa C) Latin America

9. Arrange power plants as their share in world electricity production decreases: A) hydroelectric power station B) nuclear power plant C) thermal power plant

10. Why are the main gas buyers in the northern hemisphere?

11. Why are India and China, among the top ten countries, in terms of industrial production, belong to the group of countries with low consumption of energy resources?

Grade 10. fuel and energy complex ANSWERS

Option 1

10. Why is oil transported from the countries of the Middle East along Africa and through the Suez Canal? Isn't it more profitable to carry all the oil through the Suez Canal? After all, this way of transportation is shorter.

The depth of the Suez Canal is small, so tankers with a large draft of the vessel cannot pass through it.

11. How can one explain that Japan, which ranks second in the top eight countries in terms of industrial production, is fourth in terms of consumption of primary energy resources per capita?

Japan is successfully introducing energy-saving technologies into production, which is due to necessity. Not having its own fuel, she is forced to buy it.

Option 2

10. Why are the main gas buyers in the northern hemisphere?

Gas in the countries of the "North" is used not only as a fuel, a raw material for the chemical industry, but also as a fuel for TPPs and TPPs. ( the developed countries, no or insufficient own fuel resources)

11. Why are India and China, which are among the top ten countries, in terms of industrial production, belong to the group of countries with low consumption of energy resources?

These are countries with a high population and per capita a low rate of energy consumption.

1. Russia occupies an honorable first place among the countries producing oil. Daily on site Russian Federation more than 10.124.000 barrels are produced. According to some reports, the remaining oil reserves do not exceed 50 billion barrels.More than 12% of all oil produced in the world is produced in Russia .

7th place - Samotlor 7.1 billion tons

2. Saudi Arabia It is the second country in the world in terms of oil production. Saudi Arabia produces just over 10 million barrels per day. To date, this country is the largest exporter of oil. According to some reports, a fifth of the remaining oil in the world lies in the lands of Saudi Arabia.

Al Ghawar 20 billion tons

3. USA occupies an honorable third place. According to experts, 21 billion barrels of oil lie in the lands of the United States. About 9.6 million barrels are produced daily in the United States, which is approximately 11% of all oil produced.

4. In China produce about 5% of the world's oil. This is approximately 4.3 million barrels per day. The country's total reserve is just over 20 billion barrels.

5. Iran plays very important role in the oil business. After all, the oil produced in Iran is of very high quality, which allows it to be exported for more favorable prices. Iran produces about 4.25 million barrels per day.

6. Canada. Oil business is a major industry in North America. It is Canada that is the closest supplier of oil to the United States. Meanwhile, Canada produces more than 3.3 million barrels per day.

7. Mexico. Along with Saudi Arabia and Canada, Mexico is also a supplier of oil to the United States. Pumping out about 3 million barrels daily, Mexico owns 3.5% of all oil produced in the world.

The largest in the world - Chicontepec 22.1 billion tons

8. United Arab Emirates produce about 2.8 million barrels per day, which is about 3.3% of all oil produced. However, in terms of oil reserves, the UAE is in sixth place. Today, the UAE has one of the most developed economies in Western Asia.

9. Brazil. The country has over 8.5 billion oil reserves, while producing just over 2.5 million barrels per day. In Brazil, the richest oil field is called Tupi oil Field. Carioca Sugar Loaf 11 billion tons Located in the Atlantic Ocean 330 km southeast of Sao Paulo

10. Kuwait. In this country, oil is produced at almost the same pace as in Brazil. The country is in no hurry to produce oil in large volumes. Producing just under 2.5 million barrels per day, the country knows total reserves are in excess of 104 billion barrels.

Results: Russia, which officially refused to export oil and produces it at the fastest pace, has almost the highest prices for gasoline. It's no secret that in many countries, including the UAE, the cost of high-quality gasoline does not exceed 3-6 rubles per liter. And only in our country, gasoline is not of the proper quality, it costs more than 25 rubles per liter, and besides, at gas stations they manage to dilute it and even brazenly not top it up. The cost of gasoline in Russia is much lower. After all, more than 60% of the final cost is fees, taxes and excises.. 1 barrel oil ≈ 0.1364 tons = 136.4 oil.

The largest oil and gas companies in the world in terms of hydrocarbon production. The ranking is interesting precisely because it provides data on the production of both oil and gas, converted into conventional barrels of oil per day. This approach makes it possible to compare companies with different structure prey and understand which one is "more".

The second feature of the ranking is the inclusion of not only public and partially public corporations, but also completely state-owned, which journalists often forget about. But it is state-owned companies and even ministries of oil and gas selected countries often produce more oil and gas than well-known private giants.

In developing its hydrocarbon production, Russia is following a hybrid path: the formation of huge state-controlled companies with multibillion-dollar revenues and an opaque spending system, combined with a small number of private investors. At the same time, the fact that some of the shares of mega-companies are traded on stock exchanges makes it easier for them to obtain loans and evaluate their shares in share swap deals like Rosneft-BP. offers a translation of the ranking published on the site forbes.com, with its own explanations and additions.

1. Saudi Aramco– 12.5 million b/d (conditional barrels of oil per day)

State Oil and Gas Company of Saudi Arabia. In fact, it acts as a balancing force in the world oil market, increasing and decreasing production depending on the movement of stock prices.

2. Gazprom– 9.7 million b/d

Russian company controlled by the state. The main part of the produced hydrocarbons is gas, although Gazprom owns almost 100% of the shares of the large oil company Gazprom Neft (formerly Sibneft). State after a few legal entities owns a little more than 50% of Gazprom's shares. However, the real power in the company is held by a group of managers closely associated with the "Petersburg" political and business grouping. Financial flows Gazprom is served by private Gazprombank, bank-controlled"Russia" from St. Petersburg, the so-called "bank of friends of Vladimir Putin", construction contracts are carried out by companies of the same group, the country's largest insurance group SOGAZ, which is part of the "perimeter" of Gazprom, belongs to the Rossiya bank ...

3. National Iranian Oil Co.– 6.4 million b/d

Fully state-owned Iranian corporation. Recently, it has been experiencing sales difficulties due to sanctions imposed on oil exports from Iran by Western countries. Nevertheless, Iran successfully cooperates with India, Turkey and China, supplying them with oil in exchange not only for dollars, but also, for example, for gold or yuan.

4. ExxonMobil– 5.3 million b/d

The largest private oil and gas company in the world with an annual revenue of about $500 billion. Unlike most other oil and gas corporations, it is truly global, operating in dozens of countries around the world. One of the most hated corporations in the world, mainly for its tough international politics and disregard for fashion values - from "green" to "blue".

(no number) New Rosneft- 4.6 million b/d

After merging with TNK-BP, Rosneft will become the world's largest publicly traded oil company. Gazprom and ExxonMobil, which are ahead of it in the ranking, have the main (or significant) share in production of gas. It is sometimes mistakenly said that Rosneft will become the world's largest private oil company. This is wrong, since the public status (that is, the listing of part of the shares on the stock exchange) does not mean that the company is controlled by private shareholders. Rosneft was, is and will remain under the control of the state, despite the possible continuation of partial privatization.

5. petrochina– 4.4 million b/d

The state-controlled Chinese oil and gas company is the largest of China's three oil giants. It was once the largest public company in the world, but has since fallen in price. In many ways, it is similar to the Russian Rosneft (connections in the country's leadership, fulfillment of political and economic government orders, etc.), adjusted for scale - the Chinese company is still several times larger.

6. BP– 4.1 million b/d

British "special company" to work with unpleasant regimes. At one time, she managed to work in many "hot spots", bringing income to her country and shareholders. AT last years concentrates efforts on oil production in the USA and in Russia. After the deal on TNK-BP, it will become the largest private shareholder in Rosneft. Company controlled oil production due to this deal will fall by almost a third, but cooperation with the Russian oil near-monopoly can bring additional financial income. And there's no need to worry about BP's reputation - what's the point of worrying about something that never happened?

7. Royal Dutch Shell– 3.9 million b/d

The European analogue of ExxonMobil is a completely private Anglo-Dutch global corporation with traditional oil industry ideas about business ethics. Actively works in Africa and in Russia.

8. Pemex(Petróleos Mexicanos) – 3.6 million b/d

Mexican state oil producer with extremely poor management. Despite the presence in the country of one of the world's largest oil companies, Mexico imports gasoline, since the profits from the sale of oil are not used to invest in processing, but to government (including social) programs.

9. Chevron– 3.5 million b/d

An international oil and gas and energy corporation headquartered in the United States. In addition to the extraction and processing of hydrocarbons, it is engaged in the production of electricity, including being actively involved in "alternative" energy projects. The main production facilities are located in the USA, Australia, Nigeria, Angola, Kazakhstan.

10. Kuwait Petroleum Corp.– 3.2 million b/d

The state oil and gas holding of Kuwait, which controls many mining and processing companies. Oddly enough, it is very widely represented on the retail gasoline market in Denmark, Sweden, Belgium, the Netherlands under the brands Q8, OKQ8, Q8 Easy.

11. Abu Dhabi National Oil Co.– 2.9 million b/d

State Oil and Gas Company of the United United Arab Emirates. Among other things, it is a major partner of the US government, including supplying fuel to US troops.

12. Sonatrach– 2.7 million b/d

Algerian state-owned company, mainly gas. It is also engaged in oil production, petrochemical production and energy. One of Gazprom's main competitors in Europe.

13. Total– 2.7 million b/d

The French oil and gas company is known for its funny mustache and glasses. CEO Christophe de Magerie and the fact that 3% of the company's shares belong to Qatar and about the same to China. Total is entering the liquefied natural gas market and is likely to start supplying it in 2015.

14. Petrobras(Petróleo Brasileiro) – 2.6 million b/d

More than 60% of the shares belong to the government of Brazil, the rest of the papers are traded on stock exchanges in New York and Sao Paulo. The Brazilian corporation made history with the largest one-time public offering on the stock exchange: in September 2010, securities were sold for $ 72.8 billion. The company fights for the rights of whales, which does not prevent it from drilling deep-sea wells in the ocean.

15. Rosneft– 2.6 million b/d

Igor Ivanovich Sechin and his friends.

16. Iraqi Oil Ministry– 2.3 million b/d

Iraqi Oil Ministry.

17. Qatar Petroleum– 2.3 million b/d

Qatar State Oil and Gas Company, future world Gazprom. World leader in natural gas liquefaction projects.

18. Lukoil– 2.2 million b/d

The general sponsor football team Spartak Moscow).

19. Eni– 2.2 million b/d

A global Italian oil and gas company operating in dozens of countries around the world. It has a large network of petrol stations under the Agip brand. Main hallmark- a logo with a six-legged dog spewing fire. They say that the artist created it under the influence of the legend of the Nibelungs, but according to another version, completely different substances influenced him. A little more than 30% of the company's shares are directly and indirectly owned by the state, the rest is traded on stock exchanges. By law, no investor (except the Italian state) has the right to concentrate more than 3% of the shares, do not even try.

20. Statoil– 2.1 million b/d

Norwegian oil and gas company, 2/3 of whose shares are owned by the state. Foundation of Norwegian socialism. The current main competitor of Gazprom in Europe.

21. ConocoPhillips– 2 mln b/d

American private corporation. In recent years, it has become famous for two controversial actions: the purchase and subsequent quick sale of a large stake in Lukoil (up to 18%), as well as the spin-off and sale of an oil refining division. Now ConocoPhillips is perhaps the world's only major only-extracting oil company.